Over the past decade, artificial intelligence (AI) has revolutionized numerous industries, and the field of advanced concrete technology is no exception. The integration of AI techniques has led to critically important advancements in concrete production, quality control, and construction processes, paving the way for more efficient, sustainable, and innovative solutions in the industry.

One of the most prominent applications of AI in concrete technology is in mix design optimization. Traditional methods of concrete mix design frequently enough relied on trial and error, which was time-consuming and resource-intensive. However, AI algorithms, such as neural networks and genetic algorithms, can now analyze vast amounts of data to predict optimal mix proportions for desired concrete properties. These AI-driven approaches consider multiple variables simultaneously,including material characteristics,environmental conditions,and performance criteria,resulting in more precise and efficient mix designs.

Quality control and assurance have also been greatly enhanced through the implementation of AI techniques. Machine learning algorithms can analyze real-time data from sensors embedded in concrete structures, detecting anomalies and predicting potential issues before they become critical. This proactive approach to quality control has led to improved durability, reduced maintenance costs, and extended lifespans of concrete structures.

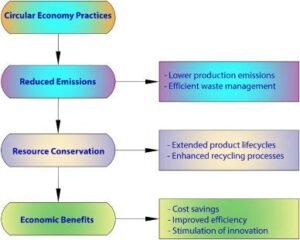

AI has also made significant contributions to the field of sustainable concrete production. By optimizing resource utilization and energy consumption during the manufacturing process, AI models have helped reduce the carbon footprint of concrete production. These systems can identify opportunities to incorporate alternative materials, such as fly ash or slag, without compromising the strength or durability of the final product. This has led to the development of more environmentally friendly concrete formulations that meet or exceed traditional performance standards.

The use of AI in predictive maintenance has been another game-changer for the concrete industry.By analyzing data from sensors embedded within buildings and infrastructure,AI algorithms can predict when maintenance is required before issues become critical. This approach extends the lifespan of structures while reducing maintenance expenses and minimizing downtime.

In recent years, the integration of AI with other emerging technologies has opened up new possibilities in concrete construction. For example, AI-powered 3D printing techniques are being developed to create complex concrete structures with unprecedented precision and speed. These systems can optimize material usage, reduce waste, and enable the creation of intricate designs that were previously impractical or impractical to construct using traditional methods.

AI has also played a crucial role in enhancing safety measures on construction sites. Computer vision and machine learning algorithms can analyze real-time video feeds to detect potential hazards, ensure proper use of protective equipment, and monitor worker behaviour. This has led to a significant reduction in accidents and improved overall workplace safety in the concrete industry.

The past decade has also seen remarkable progress in the development of self-healing concrete using AI techniques. These innovative materials incorporate bacteria or capsules containing healing agents that activate when cracks occur. AI algorithms help optimize the distribution and activation of these self-healing mechanisms, resulting in more durable and long-lasting concrete structures.

As we look to the future, the potential for AI in advanced concrete technology continues to grow.Researchers are exploring the use of deep learning techniques to develop more accurate models for predicting concrete behavior under various conditions. These models could lead to the design of ultra-high-performance concretes tailored for specific applications, from extreme environments to space exploration.

The integration of AI with Internet of Things (IoT) devices is also expected to revolutionize concrete monitoring and maintenance. Smart sensors embedded in concrete structures will provide real-time data on structural health, allowing for more efficient and targeted maintenance strategies.

the past decade has witnessed remarkable progress in the application of AI techniques to advanced concrete technology. From mix design optimization to quality control,sustainability,and safety,AI has transformed nearly every aspect of the concrete industry. As these technologies continue to evolve and integrate with other emerging innovations, we can expect even more exciting developments in the years to come, leading to stronger, more durable, and more sustainable concrete structures that will shape the built environment of the future.