In a groundbreaking growth that promises to revolutionize the construction industry, researchers have unveiled a remarkable process that transforms old concrete into new building materials while simultaneously trapping carbon dioxide. This innovative approach to urban mining not only addresses the pressing issue of construction waste but also tackles the environmental challenges posed by cement production, one of the largest contributors to global CO2 emissions.

The process, developed by a team of scientists at the University of Tokyo, represents a significant leap forward in sustainable construction practices.At its core, the technique involves grinding old concrete from demolished buildings into a fine powder, exposing it to CO2 for carbonation, and then mixing it with a calcium bicarbonate solution.This mixture is then compressed in layers within a mold and heated to form sturdy, large-scale bricks suitable for constructing houses and pavements.

Professor Ippei Maruyama, who led the research team, explains the potential of this breakthrough: “We can make calcium carbonate concrete bricks large and strong enough to build regular houses and pavements. These blocks can theoretically be used semipermanently through repeated crushing and remaking, a process which requires relatively low energy consumption.” This circular approach to construction materials means that concrete in old buildings can now be viewed as an urban mine for creating new structures, drastically reducing the need for new raw materials.

The implications of this development are far-reaching. The construction industry has long grappled with its significant environmental footprint, especially due to the production of Portland cement, a key ingredient in traditional concrete. Cement manufacturing alone accounts for approximately 8% of global CO2 emissions. By providing a method to recycle old concrete and simultaneously capture carbon dioxide, this new process addresses two critical environmental concerns at once.

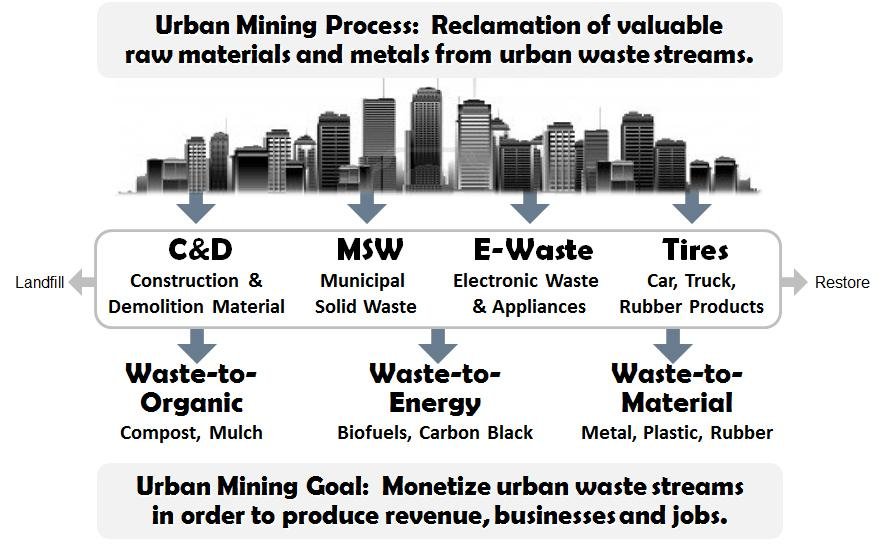

The benefits of this urban mining technique extend beyond emissions reduction. It also offers a solution to the growing problem of construction and demolition waste. In Europe alone, about 850 million tons of construction demolition materials were generated in 2020, representing more than a third of all waste produced in the region. By treating this waste as a valuable resource rather than a burden, the new process aligns perfectly with the principles of a circular economy.

The researchers demonstrated the effectiveness of their method by using concrete from a demolished school building, proving that even aged materials can be successfully recycled. The resulting bricks exhibit high density, compressive strength, tensile strength, and Young’s modulus – key indicators of their suitability for construction use. These properties suggest that the recycled material could potentially match or even exceed the performance of conventional concrete.

Moreover, this innovative process accelerates the natural carbonation of concrete, effectively turning urban structures into carbon sinks. As buildings age, they naturally absorb CO2 from the atmosphere, but this occurs very slowly. The new method speeds up this process significantly, allowing for more efficient carbon capture during the recycling phase.

The potential impact of this technology on urban development and sustainability is immense. Cities could potentially become self-sustaining in terms of construction materials, with old buildings serving as the raw material for new ones. This localized approach to sourcing building materials could also lead to reduced transportation costs and emissions associated with moving heavy construction materials over long distances.

Though, as with any emerging technology, questions remain about its scalability and economic viability. The research team is actively addressing these concerns through their ongoing project, C4S (Calcium Carbonate Circulation System for Construction). They have aspiring plans to construct a real two-story house using this technology by 2030 and are working towards establishing a pilot plant to improve production efficiency and explore industrial applications.

The development of this urban mining technique comes at a crucial time when the global construction industry is under increasing pressure to reduce its environmental impact. With the world’s population continuing to grow and urbanize, the demand for new buildings and infrastructure is set to soar. Technologies that can meet this demand while minimizing environmental harm are therefore of paramount importance.

This breakthrough also aligns with broader efforts in the construction industry to develop more sustainable practices. From high-performance and ultra-high-performance concretes that use less material to achieve greater strength, to self-healing concretes that can repair their own cracks, innovations are emerging that promise to make our built environment more durable and environmentally kind.

The success of this urban mining technique could potentially inspire similar approaches in other industries, encouraging a more circular approach to resource use across various sectors. It exemplifies how innovative thinking can turn waste into a valuable resource, challenging our traditional linear models of production and consumption.

As we look to the future, the potential of urban mining extends beyond just concrete. Other construction materials such as steel, glass, and even electronic components from smart buildings could potentially be recycled and reused in similar ways. This holistic approach to urban resource management could play a crucial role in creating more sustainable, resilient cities.

the breakthrough in transforming old concrete into new building materials while trapping CO2 represents a significant step towards a more sustainable construction industry. By turning urban demolition waste into a valuable resource and sequestering CO2 in the process, this technology offers hope for a future where construction becomes part of the solution to climate change, rather than a contributor to the problem. As research continues and the technology is refined, we might potentially be witnessing the dawn of a new era in sustainable urban development, where our cities not only house us but also serve as reservoirs of materials for future growth.