The narrative of Portland cement commences in the late 18th century, originating from experimental combinations of limestone and additives. John Smeaton initiated this journey in 1756 through his pioneering work with various limestones and supplementary materials, including trass and pozzolanas, while constructing what would later be recognized as Smeaton’s Tower. This foundational exploration established the groundwork for a building material that would transform construction methodologies worldwide. The material underwent swift evolution during subsequent decades.

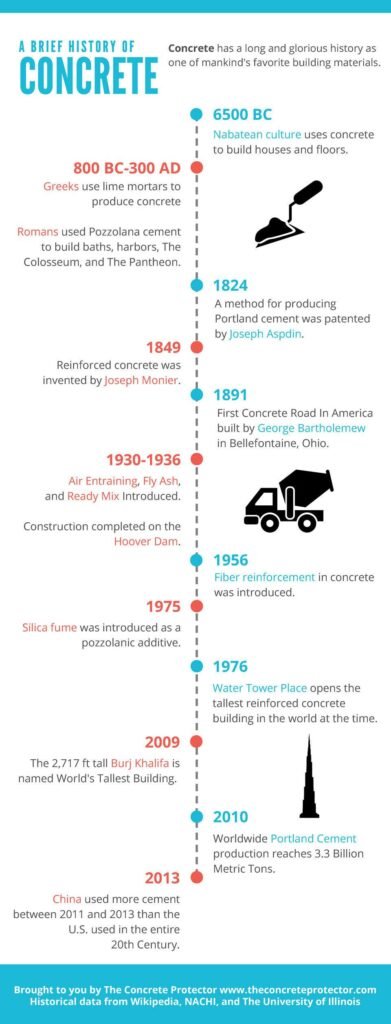

Joseph Aspdin, a British bricklayer with inventive aspirations, formalized the concept in 1824 by heating limestone and clay until calcination occurred, then pulverizing the mixture and combining it with water. He christened his creation “Portland Cement” due to its visual similarity with Portland stone, a robust building material quarried on Dorset’s Isle of Portland. Although Aspdin’s initial formulation bears minimal resemblance to contemporary Portland cement, it represented a crucial stepping stone toward modern formulations and has been characterized as “proto-Portland cement”.

The material experienced noteworthy refinement in 1843 when William Aspdin, Joseph’s son, implemented vigorous heating techniques alongside improved grinding equipment capable to process the hardened clinker. The advancement trajectory continued when Isaac Johnson elevated firing temperatures to approximately 1400-1500°C in 1845, causing the mixture to clinker and essentially producing what constitutes modern-day cement. These sequential improvements established the fundamental characteristics of Portland cement as we understand it presently.

The nomenclature “Portland cement” appears in published records from 1823, associated with William Lockwood and potentially other contemporaries. Despite this documentation of the name, the material itself was undergoing continual modification. The first standardization of Portland cement emerged in Germany in 1878, which outlined initial test methodologies and minimum property requirements, with numerous other countries subsequently establishing their own specifications. This standardization framework provided the consistency necessary for reliable application across varied construction contexts.

Portland cement migrated to the United States during the nineteenth century, where its development trajectory continued. During spring 1866, David O. Saylor, Esias Rehrig, and Adam Woolever established the Coplay Cement Company, initiating American participation in cement production. This transatlantic adoption marked the beginning of global proliferation that would ultimately position Portland cement as the predominant building material throughout industrialized and developing regions alike.

Manufacturing processes have evolved substantially throughout two centuries of development. The material typically undergoes production via two principal methodologies, involving precise combinations of limestone, clay, and other elements subjected to carefully controlled thermal processing. The resulting clinker requires meticulous grinding to achieve proper particle distribution for optimal performance characteristics.

Contemporary cement production confronts environmental challenges that were unforeseen by early pioneers. The industry contributes significantly towards global carbon emissions through chemical reactions inherent to limestone processing and energy-intensive kiln operations. Manufacturers now explore alternative formulations incorporating supplementary cementitious materials like fly ash and slag to reduce the environmental footprint associated with traditional production methods. These innovations sometimes compromise certain performance parameters while enhancing others, requiring careful balance among competing objectives.

Modern research emphasizes carbon capture technologies, modified kiln designs, and novel binding agents that might eventually replace portions of conventional Portland cement. Though progress occurs steadily, widespread implementation faces economic barriers and regulatory hesitation due to construction codes optimized around traditional formulations.

The history of Portland cement illuminates how incremental innovation transforms rudimentary materials into sophisticated products that underpin civilization’s physical infrastructure. From Smeaton’s experimental mixtures to today’s precisely engineered composites, Portland cement exemplifies humanity’s capacity to refine natural materials through scientific understanding and practical application. As sustainability concerns drive contemporary development, the material enters its third century poised for further transformation—though the ghost of its historical origins remains visible in every modern formulation.